Cold Room Temperature Monitoring for Food Stores

Remote Temperature and Humidity Monitoring for Freezers and Coolers

The SensMax SensGuard remote temperature and humidity monitoring system provides continuous control of storage conditions in freezers, coolers, cold rooms and warm displays. Stable temperature helps protect food quality, reduce spoilage and support HACCP temperature monitoring and local food safety requirements. The system sends instant alerts when temperature values go outside the allowed range.

What the freezer and cooler monitoring system does

SensGuard is a remote temperature monitoring system for freezers, coolers and cold rooms. Wireless sensors measure conditions inside refrigeration equipment and storage areas and send readings to the cloud every 5 minutes. This gives facility teams and store managers a clear view of refrigerator temperature, incident duration and recurring deviations.

If temperature rises above or drops below the allowed range, food spoilage may occur and products may need to be written off. Remote monitoring helps detect excursions early and react before the incident becomes critical.

Why remote monitoring matters for food retail and cold storage

Refrigeration issues can develop between manual checks: door left open, blocked airflow, defrost problems, failing compressors or incorrect setpoints. A remote monitoring system provides early warning and helps document compliance with HACCP procedures.

- Early detection of refrigerator and freezer temperature excursions

- Reduced product loss and fewer write-offs due to spoilage

- Audit-ready temperature history for HACCP and internal inspections

- Incident tracking with duration and alarm history for root-cause analysis

- Coverage for sites with limited on-site staff (evenings, weekends, small stores)

Use cases

- Supermarkets and hypermarkets — monitoring freezers, coolers, upright fridges and open showcases

- Convenience stores and fuel stations — tracking beverage fridges and small freezers with limited staff

- Butcher, fish and deli counters — monitoring service counters and back-room refrigeration

- Back-of-store cold rooms — controlling temperature in storage zones not visible to customers

- Bakery and warm displays — monitoring elevated temperatures where stability is also important

Typical installation points for wireless sensors in freezers, coolers and cold rooms.

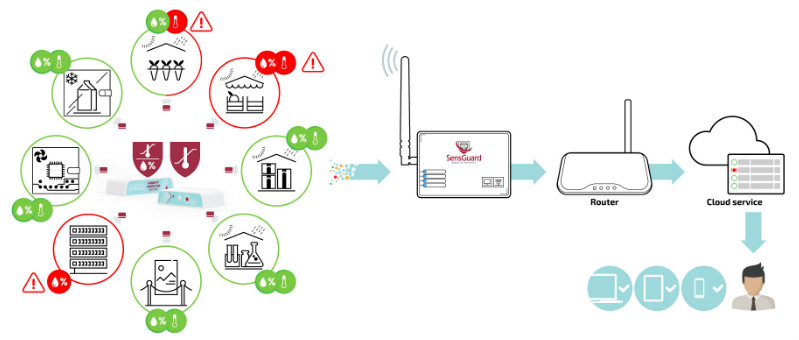

How the SensGuard system works

Sensors measure temperature (and humidity where required) every 5 minutes and send readings to the SensMax TCP LR X2 gateway, which transmits them to the SensGuard cloud platform. Each sensor has its own min/max thresholds and allowed violation time.

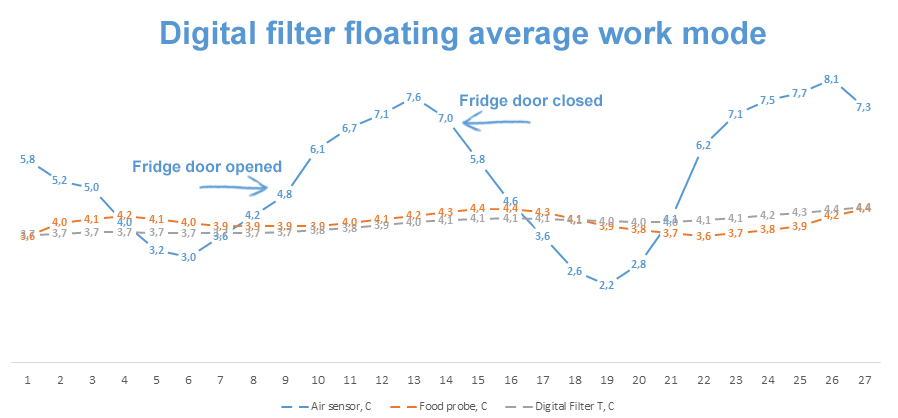

For refrigeration equipment with automatic defrost, SensGuard supports a defrost handling mode so short-term temperature rises during defrost cycles do not trigger unnecessary alarms. For frequent door openings, the DigitalFilter function can help reduce alarms from short peaks by smoothing short-term fluctuations.

SensGuard online monitoring architecture for food retail refrigeration.

The SensGuard solution consists of three main components:

- Wireless temperature and humidity sensors installed in each freezer, cooler or cold room

- SensMax TCP LR X2 gateway that collects sensor readings and sends them to the cloud

- SensGuard cloud software that displays readings, alarms and reporting history

Wireless sensors are battery-powered and can operate for up to 5 years. One gateway collects data from up to 250 sensors within 150 m and includes buffer memory to prevent data loss during temporary Internet outages.

Request cold chain monitoring consultation

Hardware used in this solution

Different refrigeration equipment may require different sensor types. SensMax provides waterproof sensors for standard ranges and probe sensors for deep freezers and technical installations.

| Device | Type | Temperature range | Accuracy | Resolution | Battery / Power | Typical use |

|---|---|---|---|---|---|---|

| MCP9800 wireless temperature sensor | Waterproof sensor | −20°C…+55°C | ±0.5°C | 0.1°C | up to 5 years | Standard freezers, coolers and upright fridges (temperature monitoring). |

| ENS210 wireless temperature & humidity sensor | Temperature & humidity sensor | −20°C…+55°C / 0–100% RH | ±0.5°C / ±3.5% RH | 0.1°C | up to 5 years | Cold rooms and storage areas where humidity affects product quality. |

| DS18B20 probe-type wireless temperature sensor | Probe sensor | −30°C…+120°C | ±0.5°C | 0.1°C | up to 5 years | Deep freezers, blast freezers and installations where the probe must be placed inside the chamber. |

| PT100 probe-type high-range wireless temperature sensor | High-range probe sensor | −50°C…+200°C | ±0.2°C | 0.1°C | up to 5 years | Warm displays, baking equipment and higher-temperature monitoring points. |

Defrost handling and temperature filtering

Automatic defrost cycles can cause short-term temperature rises that should not be treated as incidents. SensGuard supports defrost handling mode to filter out expected peaks during defrost. For frequent door openings, DigitalFilter can smooth short spikes and help reduce unnecessary alarms while keeping incident detection reliable.

DigitalFilter reduces short-term temperature peaks and helps avoid alarms from brief fluctuations.

Reporting and HACCP compliance

SensGuard stores temperature history, alarm events and user comments and supports export to CSV files and PDF reports. This helps document cold chain monitoring procedures and supports HACCP temperature monitoring in food retail and cold storage operations.

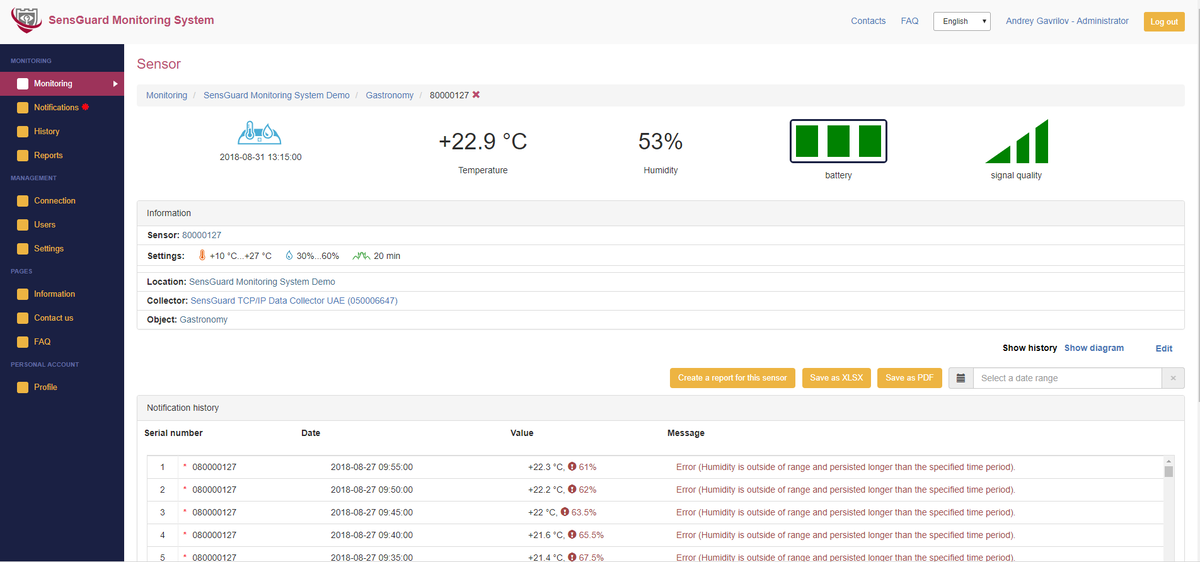

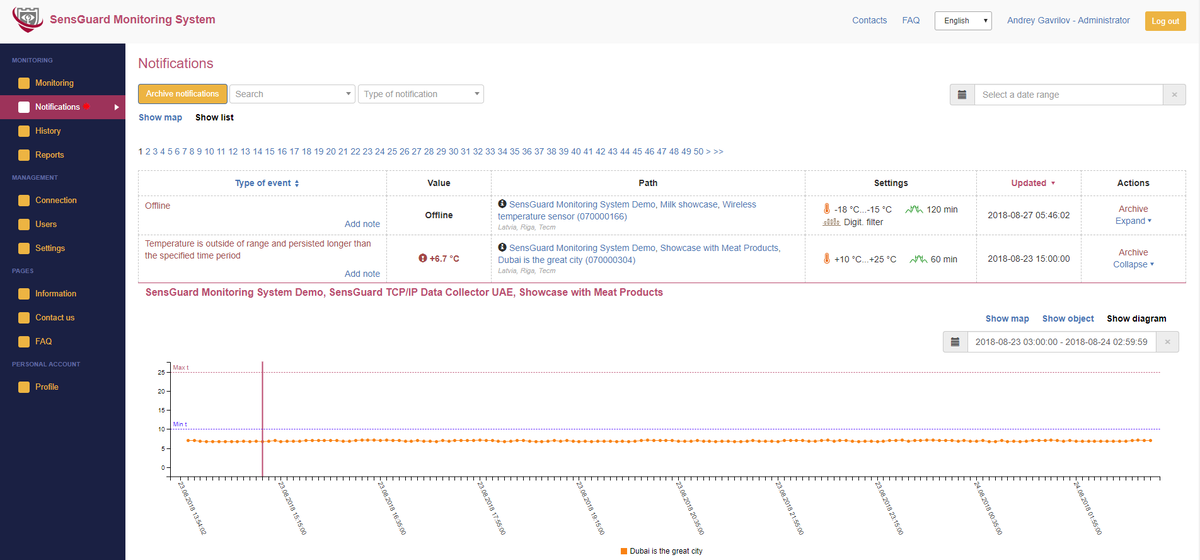

SensGuard cloud software

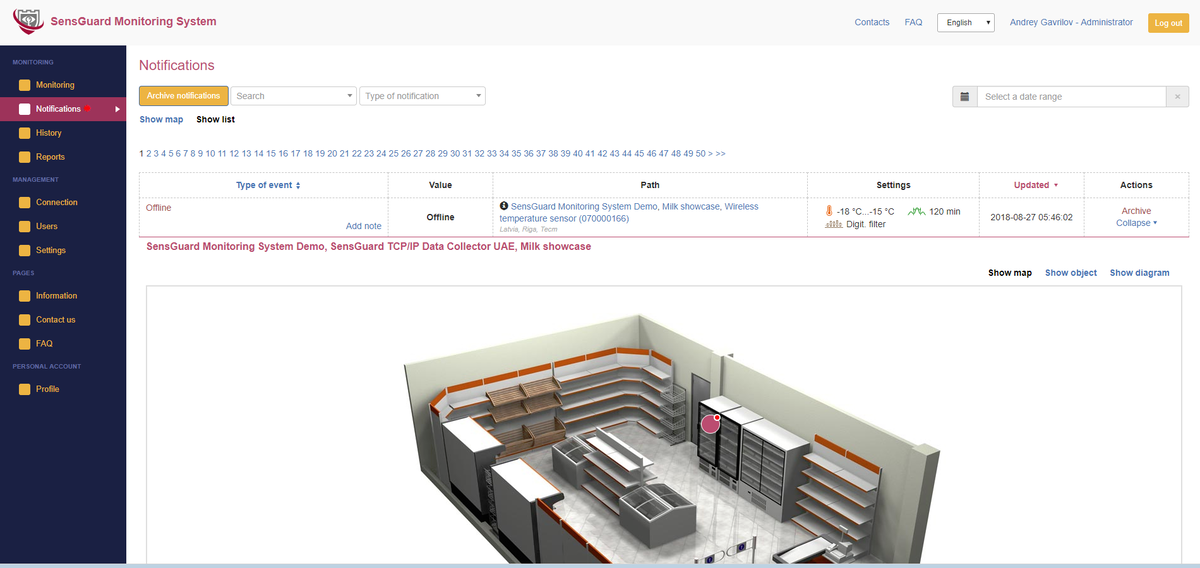

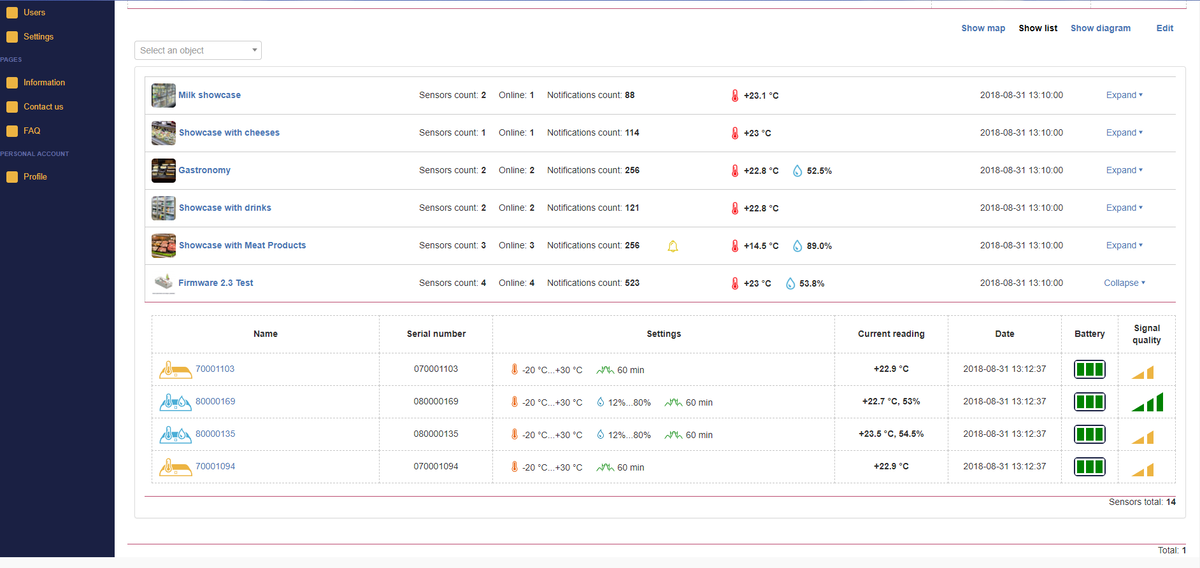

The SensGuard portal displays readings for each sensor or sensor group. Users can:

- set min/max ranges and receive alerts when temperature goes outside limits

- upload a store map and place sensors on it to locate the affected freezer or cooler quickly

- configure e-mail and Telegram notifications by user role

- review alarm history, comments and incident duration

- analyse trends to detect early signs of equipment issues or door-usage patterns

The system supports data export as CSV files and PDF reports to archive temperature history and use reports during inspections or internal audits.

Store map view with sensors placed on freezers and showcases to locate incidents faster.

Monitoring list of refrigeration equipment with current readings and status indicators.

Detailed sensor readings with alarm history for incident analysis.

Temperature stability view showing alarm periods over time.

Request a quote for freezer monitoring system