Warehouse Temperature & Humidity Monitoring

Remote Temperature and Humidity Monitoring for Warehouses

Warehouses and logistics facilities have large spaces, frequent door openings and uneven airflow. The SensMax SensGuard remote temperature and humidity monitoring system helps keep storage conditions under control across all zones, protect goods from climate-related damage and support stable operations. The system provides real-time visibility and instant notifications so teams can react before problems escalate.

What the warehouse climate monitoring system does

SensGuard provides continuous warehouse temperature monitoring and warehouse humidity monitoring across aisles, racks, loading areas and storage rooms. Wireless sensors measure conditions every 5 minutes and send readings to the cloud, where they are compared with thresholds set for each zone.

This helps detect risks caused by HVAC malfunctions, humidity spikes, prolonged loading bay openings, poor ventilation or local heat sources near doors and unloading areas. With early alerts, warehouses can reduce product loss, protect packaging integrity and keep storage conditions consistent for temperature- and humidity-sensitive goods.

Why temperature and humidity monitoring matters in warehouses

Conditions inside warehouses can vary strongly between zones, especially near loading docks, high racks, doors and semi-outdoor areas. Remote monitoring helps identify problem zones early and provides documented history for audits, storage agreements and internal quality control.

- Early warning of HVAC issues and local hotspots near docks and doors

- Humidity control for packaging, dry goods, ingredients and stored materials

- Zone-based thresholds for different storage requirements in the same facility

- Trend history for investigations and recurring problem detection

- Remote visibility for multi-hall warehouses and distributed logistics sites

Use cases

- Distribution warehouses — monitoring conditions across multiple halls and long aisles

- Logistics centers — supervising climate during receiving, cross-docking and dispatch operations

- Dry material warehouses — tracking humidity for cardboard, powders, packaging and ingredients

- High-rack storage — monitoring temperature variation at different height levels

- Semi-outdoor or unheated storage areas — detecting rapid changes caused by weather and ventilation

Wireless sensors installed across warehouse aisles, storage zones and high-rack areas.

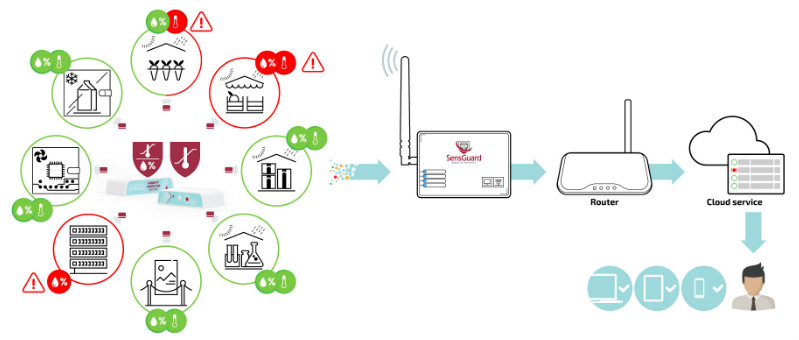

How the SensGuard system works

Warehouse environments change during daily operations: loading bay traffic, forklift movement, door openings, ventilation cycles and HVAC load shifts. SensGuard measures temperature and humidity every 5 minutes and generates alarms only when deviations exceed the configured limits longer than the allowed violation time.

SensGuard monitoring architecture for large warehouse environments.

The system includes three components:

- Wireless temperature and humidity sensors installed across aisles, racks and storage rooms

- SensMax TCP LR X2 gateway that collects sensor readings and sends them to the cloud

- SensGuard cloud software that visualises current conditions, alerts and long-term trends

Sensors are battery-powered and can operate for up to 5 years. One gateway supports up to 250 sensors within 150 m (up to 500 m with repeaters), which fits multi-hall warehouses and large floor areas. Built-in buffer memory helps prevent data loss during temporary Internet outages.

Request warehouse monitoring consultation

Hardware used in this solution

Warehouse layouts and storage requirements vary by zone. SensMax offers wireless temperature and humidity sensors suitable for general aisles, dock areas, packaging zones and high-rack storage.

| Device | Type | Temperature range | Accuracy | Resolution | Battery / Power | Typical use |

|---|---|---|---|---|---|---|

| MCP9800 wireless temperature sensor | Waterproof sensor | −20°C…+55°C | ±0.5°C | 0.1°C | up to 5 years | General warehouse aisles, storage rooms and areas near loading docks (temperature monitoring). |

| ENS210 wireless temperature & humidity sensor | Temperature & humidity sensor | −20°C…+55°C / 0–100% RH | ±0.5°C / ±3.5% RH | 0.1°C | up to 5 years | Humidity-sensitive zones such as packaging storage, dry goods areas, mezzanines and high-rack sections. |

| DS18B20 probe-type wireless temperature sensor | Probe sensor | −30°C…+120°C | ±0.5°C | 0.1°C | up to 5 years | Equipment monitoring and special zones requiring probe placement near a specific component or inside a cabinet. |

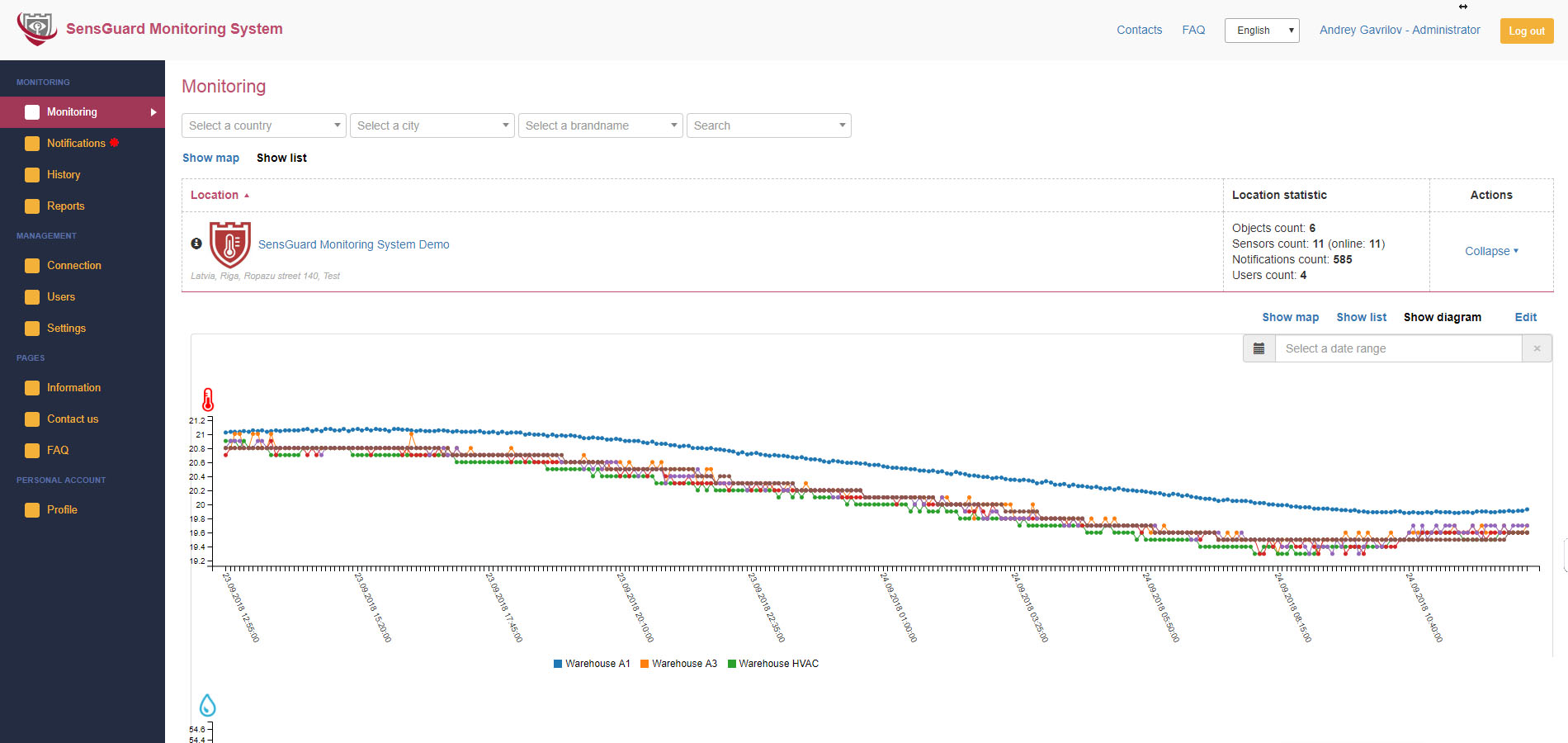

Reporting and audit support

SensGuard logs temperature and humidity history, alarm events, incident duration and user comments. This helps trace environmental problems, compare zones and document storage conditions for internal standards, customer requirements and quality audits.

Data can be exported as CSV files or PDF reports for investigations, reporting and documentation.

Recommended configuration for a typical warehouse

- 10–50 wireless sensors depending on facility size, hall count and monitored zones

- 1–2 SensMax TCP LR X2 gateways with LAN/Internet connection

- SensGuard cloud accounts for warehouse management, operations staff and technical personnel

- Automatic notifications via e-mail and Telegram messenger for on-duty staff

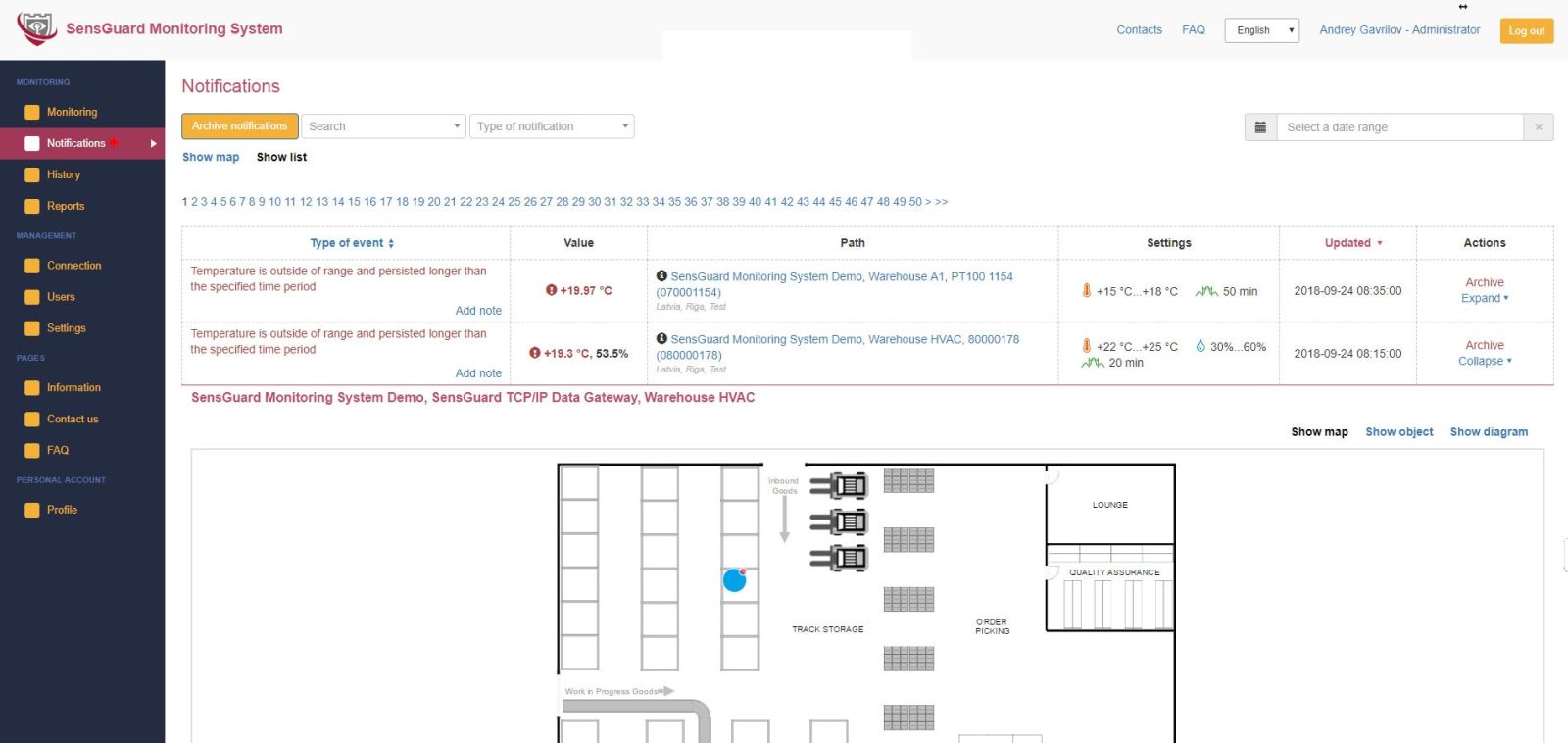

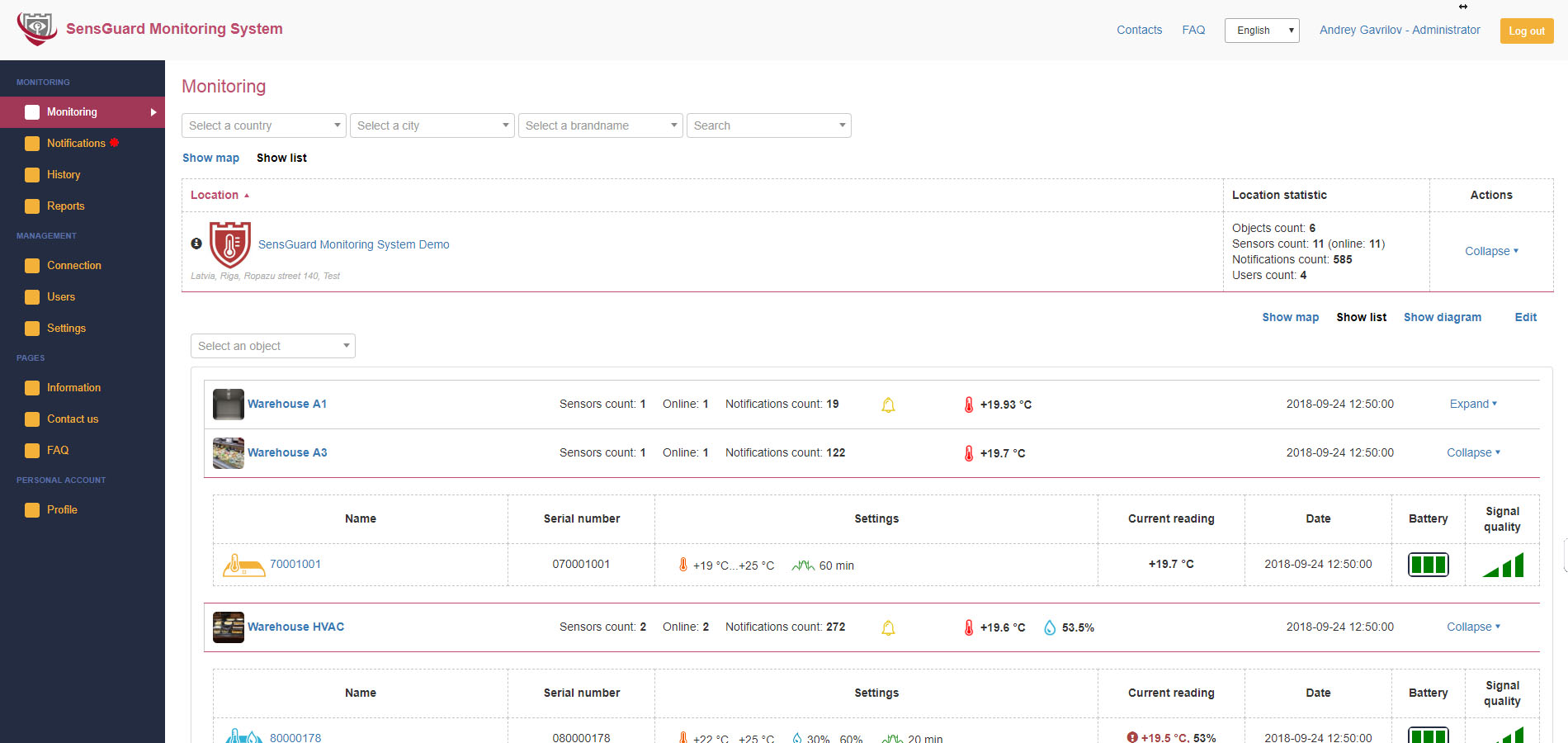

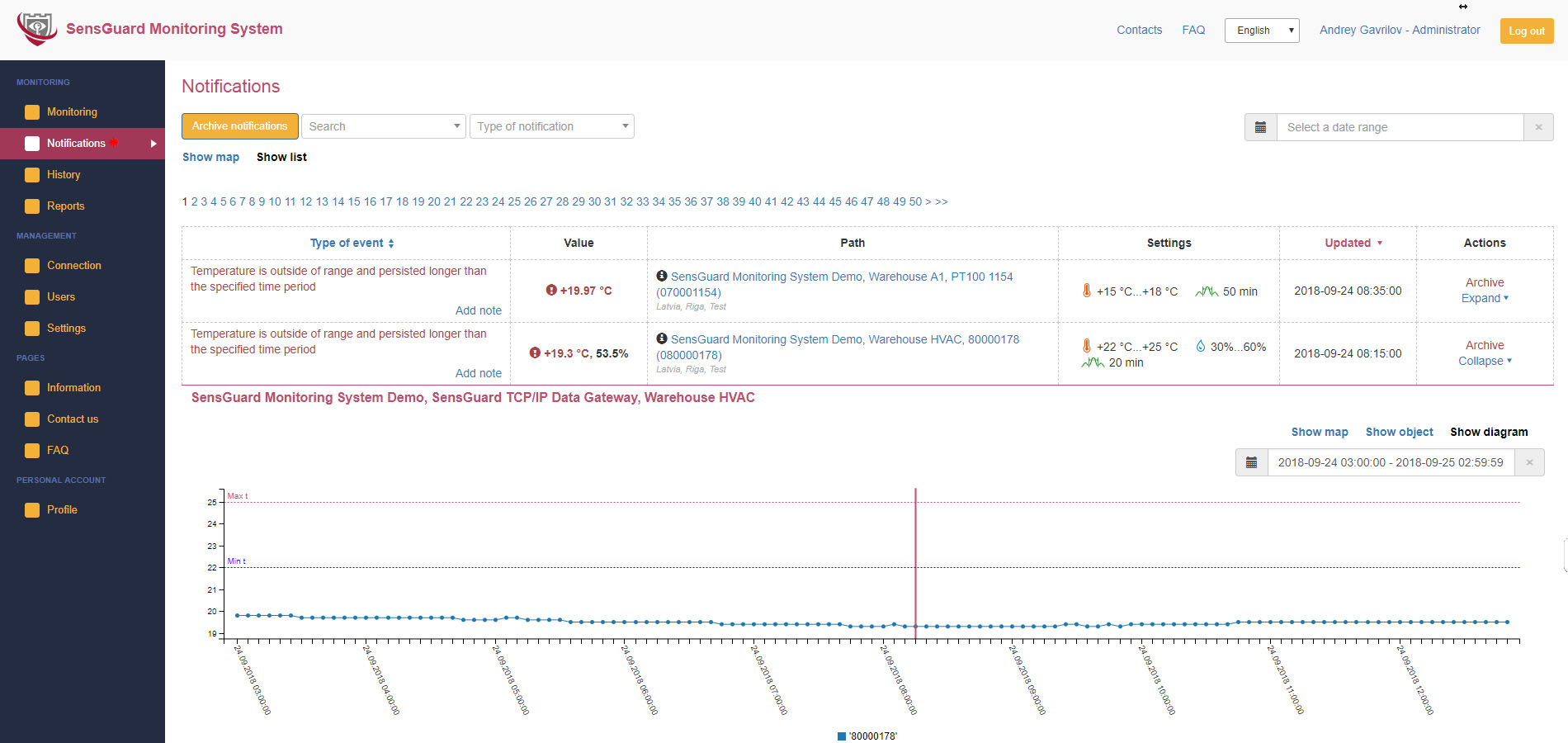

SensGuard cloud software

The SensGuard cloud platform gives warehouse teams a full overview of conditions across all zones. Users can:

- view real-time readings for each storage zone on a single dashboard

- upload a warehouse map and place sensors to locate affected zones faster

- set individual ranges and allowed violation time per sensor

- assign users to specific halls, storage rooms or site locations

- review alarm history with incident duration and staff comments

- analyse long-term trends to detect HVAC or ventilation issues early

- export CSV and PDF reports for audits and investigations

FAQ — Warehouse temperature and humidity monitoring

- How often does the system record values?

Sensors measure temperature and humidity every 5 minutes and send readings to the cloud through the gateway. - Can different zones have different limits?

Yes. Each sensor can have its own thresholds and allowed violation time, which fits mixed storage requirements. - What happens if the Internet connection is lost?

The gateway has buffer memory to prevent data loss during temporary Internet outages. - How many sensors can one gateway support?

Up to 250 sensors per gateway, depending on range and layout (repeaters can extend coverage). - Is this suitable for loading docks and semi-outdoor areas?

Yes. Sensors can be placed in dock-adjacent zones and unheated areas to detect rapid environmental changes. - Can I monitor conditions at different rack heights?

Yes. Sensors can be installed at different height levels to capture temperature gradients in high-rack storage.

Warehouse map view with sensors placed across aisles and storage halls.

Dashboard showing real-time temperature and humidity values for each warehouse zone.

Sensor detail page with alert history and deviation periods.

Long-term temperature and humidity trends across monitored warehouse zones.

Request a quote for warehouse monitoring